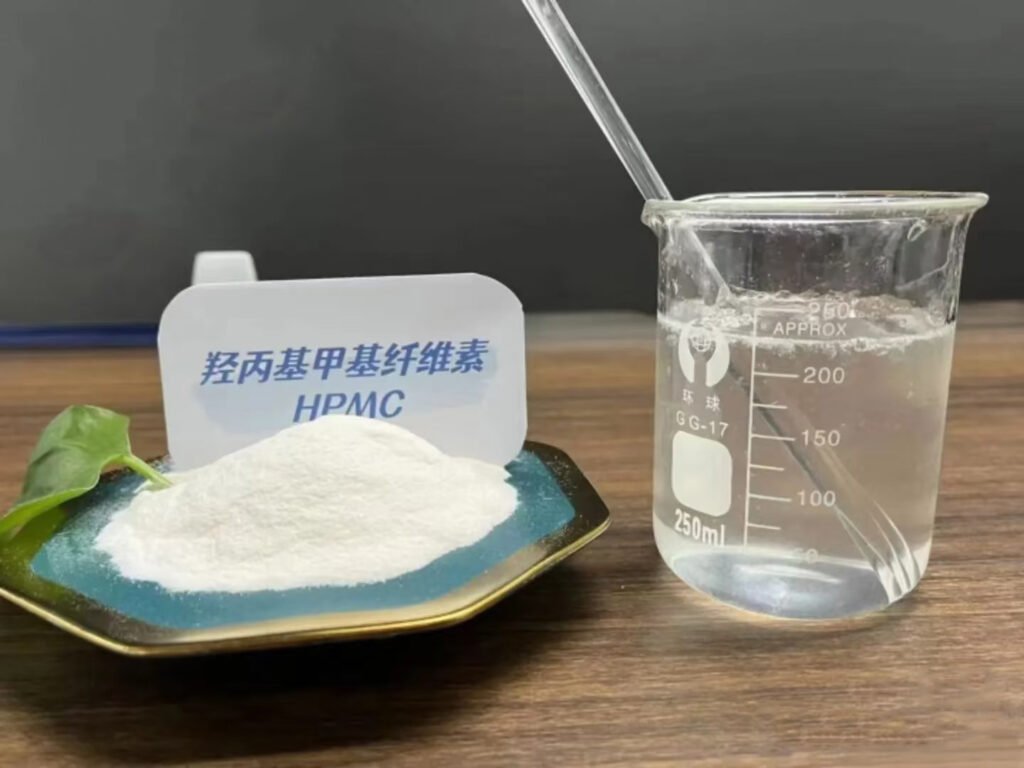

Many buyers hear about cellulose ether but still wonder what it really is, how it works, and why it matters.

Cellulose ether is a water-soluble polymer derived from natural cellulose through chemical modification. It improves thickening, binding, water retention, and film-forming performance, making it essential in construction, coatings, food, and pharmaceutical industries.

Let’s explore its uses, types, production process, and key properties.

Table of Contents

ToggleWhat Is Cellulose Ether Used For?

Cellulose ether plays a vital role in various industries due to its excellent rheological control, film formation, and water retention abilities. From construction to pharmaceuticals, its performance directly affects end-product quality.

For cellulose ether uses, the most common applications include:

| Industry | Use | Function |

|---|---|---|

| Construction | Mortar, cement, gypsum-based products | Improves workability, water retention, and adhesion; prevents cracking |

| Coatings | Water-based paints, coatings | Thickens, stabilizes, and improves film formation; enhances color development |

| Food | Baked goods, dairy products, beverages | Thickens, stabilizes, and emulsifies; controls water content and texture |

| Pharmaceuticals | Tablets, suspensions, creams | Binds, thickens, and suspends; controls drug release |

In construction, cellulose ether gives mortar better workability and water retention. This means the mortar is easier to apply and less likely to dry out too quickly. In paints, cellulose ether helps to thicken the paint, keep it stable, and make a better film. In food, it can improve the texture and stability of products like baked goods and dairy. So if you are looking for cellulose ether uses, especially cellulose ether for construction, you can see that it is used in many places, and it is worth considering for your products.

HIXEN offers customized cellulose ether solutions that meet these diverse needs. Our cellulose ether for construction and industrial grades maintain consistency and performance under different climates and batch conditions.

What Are Types of Cellulose Ethers?

There are many types of cellulose ethers. Each type has its own unique properties and uses.

Common examples of cellulose ethers include HPMC, HEC, CMC, and RDP. HPMC is often used in construction materials, while HEC is common in coatings. CMC is used in food and RDP is important in dry mix mortars.

- HPMC (Hydroxypropyl Methyl Cellulose): Known for excellent thickening and water retention. Widely used in dry-mix mortars, tile adhesives, and coatings.

- HEC (Hydroxyethyl Cellulose): Excellent for latex paints and detergents, providing stability and smooth flow.

- CMC (Carboxymethyl Cellulose): Highly effective in food and pharmaceutical formulations for viscosity control.

- RDP (Redispersible Polymer Powder): Often used with HPMC to enhance flexibility and bonding in mortars.

Each of these products—HPMC cellulose ether, CMC cellulose ether, and RDP in construction—helps manufacturers achieve optimal viscosity and durability. HIXEN supplies all these types with consistent quality and competitive cellulose ether price, ensuring reliability for industrial clients.

How Is Cellulose Ether Made?

Cellulose ether is made from natural materials. The production process changes the cellulose to give it new properties.

Cellulose ether is made by reacting cellulose with etherifying agents. This process, called etherification, replaces some of the hydroxyl groups on the cellulose molecule with ether groups.

The process starts with raw materials like wood pulp or cotton linters. These materials are mainly cellulose. The cellulose is then treated with chemicals to activate it. These chemicals make it easier for the cellulose to react with etherifying agents.

The etherification reaction happens when the activated cellulose is mixed with etherifying agents. These agents are usually alkyl halides or epoxides. The reaction replaces some of the hydroxyl groups (-OH) on the cellulose with ether groups (-OR). This changes the cellulose and gives it new properties.

The quality of the cellulose ether depends on the purity of the raw materials and the stability of the production process. At HIXEN, we use high-purity raw materials and strict quality control. This makes sure that our cellulose ether products are consistent and reliable. By focusing on quality, we can offer cellulose ethers that perform well in different applications. This helps our customers achieve the best results in their products.

What Are the Properties of Cellulose Ether?

Cellulose ether stands out for its balanced physical and chemical properties that enable its wide application across industries.

It is chemically stable, non-toxic, biodegradable, and highly compatible with other materials.

Key cellulose ether properties include:

| Property | Description | Benefit |

|---|---|---|

| Solubility | Dissolves in water to form a clear, viscous solution | Easy to use and mix in water-based systems |

| Water Retention | Retains water in mixtures | Prevents drying out too quickly, improves workability and adhesion |

| Thickening | Increases the viscosity of solutions | Improves the texture and stability of products |

| Stability | Stable over a wide range of temperatures and pH levels | Maintains performance under different conditions |

| Non-toxicity | Safe to use in food and pharmaceutical applications | Suitable for products that come into contact with people |

| Eco-friendliness | Derived from renewable resources and biodegradable | An environmentally friendly choice |

Cellulose ether is also environmentally friendly because it comes from renewable resources. It ticks many boxes in functionality and safety. When you’re considering cellulose ether, think about what properties are most important for your product. Also consider the cellulose ether price, which can vary depending on the type and grade. Contact HIXEN for more information and to get a sample or a quote.

Conclusion

Cellulose ether is a very useful substance with many applications. It’s used in construction, food, paints, pharmaceuticals and more. If you want to learn more or need a sample, contact HIXEN today.