Circulating water systems in industrial plants face constant threats from scale, corrosion, and biofilm. Without proper treatment, these issues lead to costly downtime, energy waste, and equipment damage. Circulating water treatment chemicals are scientifically formulated to optimize system efficiency and longevity. This guide explains how to choose the right chemicals for your needs.

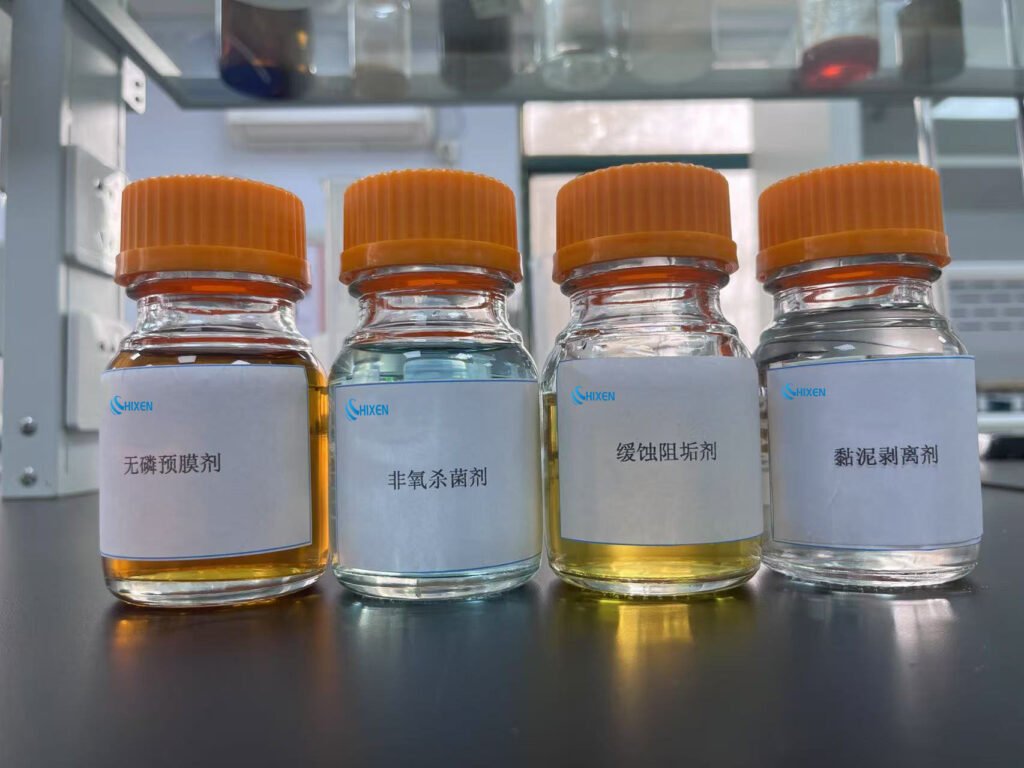

Our Circulating water chemicals mainly include Scale & Corrosion inhibitors, Non-Oxidizing biocide, Biofilm & Sludge Dispersant and Pre-Filming agent, etc. Through water treatment chemicals, we can reduce corrosion, scale, foam, and other problems, ensure the normal operation of the system, reduce unnecessary downtime, and reduce maintenance costs.

| Project | Control Indicator |

|---|---|

| Appearance | Light yellow transparent liquid |

| Density (g/cm³) | 1.128 ± 0.10 |

| pH | 2.26 ± 1.0 |

| Project | Control Indicator |

|---|---|

| Appearance | Colorless to blue-green liquid |

| Density (g/cm³) | 1.038 ± 0.05 |

| pH | 3.56 ± 0.5 |

| Project | Control Indicator |

|---|---|

| Appearance | Colorless transparent liquid |

| Density (g/cm³) | 1.04 ± 0.05 |

| pH | 3.13 ± 0.5 |

| Project | Control Indicator |

|---|---|

| Appearance | Light yellow transparent liquid |

| Density (g/cm³) | 1.2 ± 0.10 |

| pH | 2.31 ± 1.0 |

Our scale and corrosion inhibitors combine organic phosphonates, polycarboxylic acids, sulfonate copolymers, and azole compounds to effectively prevent scaling and corrosion in water systems.

Applications: Ideal for circulating water systems in power plants, chemical plants, and air conditioning systems

Our non-oxidizing biocide can be used in various water treatment systems to effectively kill bacteria. It can be used alone or in combination with other biocides for better results.

Applications: Ideal for cooling water systems in power plants, chemical plants, and air conditioning systems

The pre-filming agent is composed of a variety of complexing agents, dispersants, film-forming agents, surfactants, etc. This film has a large resistance and can isolate the metal from the corrosive media in the water, thereby inhibiting corrosion.

Directly connected to the factory, more discounts for larger minimum order quantities

Our company has passed IS09001 quality management system certification

Support production customization, customer formula, OEM and sample analysis.

Our sales staff will provide you with consulting services around the clock to solve your questions

Senior technical consultants will connect with you throughout the process to solve technical problems

Many years of experience in producing water treatment products, product quality is guaranteed

We offer a variety of payment options and our extensive inventory allows for prompt delivery without delays

Free samples, consult and get free samples, you can get product information and quotation

Circulating water treatment is crucial in modern industry, and here are six highlights that emphasize its importance.

Net weight: 25 kg (6.6 gallons)

Container: Polyethylene container

Dimensions: 30 × 23 × 47 cm

Storage temperature: Room temperature, 5~30℃.

Long-term storage: Please stir well before use to ensure the efficacy of the product.

Net Weight: 200 kg (52.8 gallons)

Container: Polyethylene container

Dimensions: 58 × 58 × 88 cm

Storage temperature: Room temperature, 5~30℃.

Long-term storage: Please stir well before use to ensure the efficacy of the product.

Net Weight: 1000 kg (264.2 gallons)

Container: Polyethylene container

Dimensions: 120 × 100 × 110 cm

Storage temperature: Room temperature, 5~30℃.

Long-term storage: Please stir well before use to ensure the efficacy of the product.

We warmly invite you to visit our water treatment chemicals production site, where you can see our advanced production lines and meet our dedicated team.

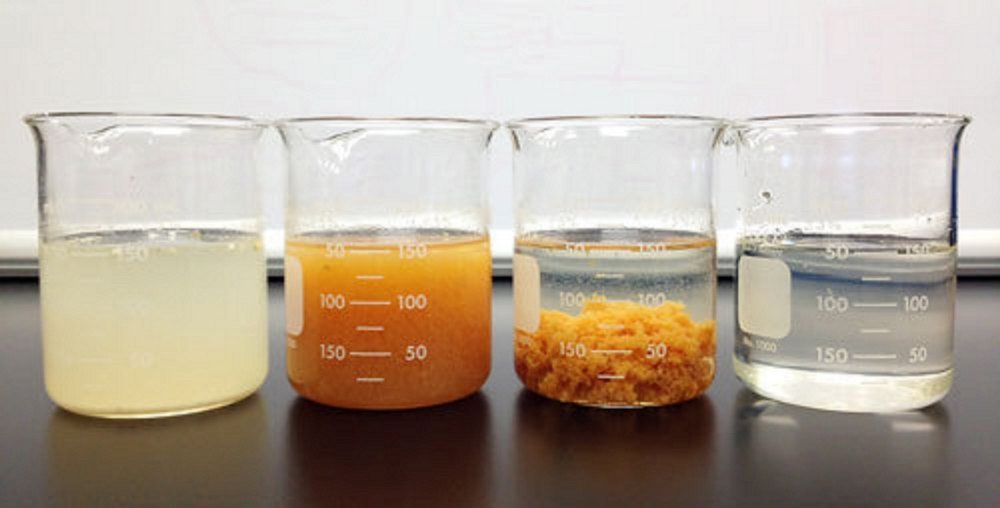

To deal with scaling and corrosion problems in Cooling Water, the following measures can be taken:

1.Water treatment

2.Equipment maintenance

3.Adjust operating conditions

4.Use anti-corrosion coatings

WhatsApp us