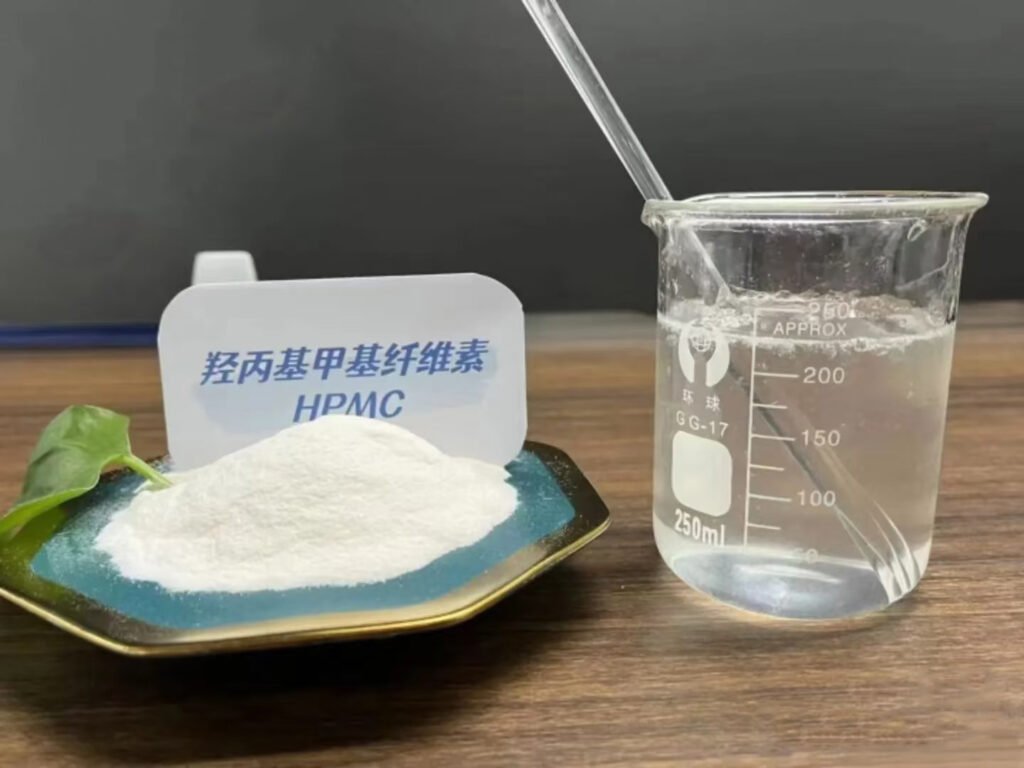

Dealing with unexplained ingredients? Hydroxypropyl Methylcellulose (HPMC) might be one of them. It’s a mouthful, but understanding it is simple. Let’s explore this common additive to see why it’s included in so many products!

HPMC (Hydroxypropyl Methylcellulose) is a non-ionic, water-soluble cellulose ether polymer. It’s used as a thickener, binder, film-former, and protective colloid in various industries, including construction, pharmaceuticals, food, and cosmetics.

Let’s dive deeper into the world of HPMC and uncover its specific uses, key characteristics, how it stacks up against other cellulose ethers, and how you can source high-quality HPMC for your specific needs.

Table of Contents

ToggleWhat is HPMC?

HPMC’s full name is Hydroxypropyl Methylcellulose, but what does that mean from a chemical and structural standpoint? It’s essentially a modified form of cellulose. This section will break down its composition and properties more simply.

HPMC is a modified cellulose derived from natural cotton or wood pulp. It’s created by reacting cellulose with methyl chloride and propylene oxide, introducing methyl and hydroxypropyl groups to the cellulose backbone.

Cellulose, the main structural component of plant cell walls, is a long chain of glucose molecules. By adding methyl (-CH3) and hydroxypropyl (-CH2CHOHCH3) groups to this chain, the properties of cellulose are altered. This modification makes HPMC water-soluble, unlike pure cellulose. The degree of substitution, i.e., the number of methyl and hydroxypropyl groups attached, determines the specific properties of the HPMC grade, influencing its solubility and viscosity. Because HPMC is non-ionic, it exhibits excellent stability in solutions, even in the presence of salts or pH changes, and is compatible with a wide range of other ingredients.

What Are The Key Properties Of HPMC?

HPMC is known for its excellent water retention, thickening, binding, film-forming, and suspension properties. It’s also odorless, tasteless, and non-toxic.

| Feature | Description | Typical Application Areas | Key Effects/Benefits |

|---|---|---|---|

| Water retention capability | Absorbs water and releases slowly, preventing rapid evaporation | Construction mortars, tile adhesives, foods, etc. | Prevents dry shrinkage cracking; maintains appropriate hydration |

| Thickening action | Increases viscosity in aqueous systems, improves rheology | Paints, coatings, personal care products, etc. | Provides excellent rheology control; improves workability and coating uniformity |

| Film quality | Forms stable films with good film-forming properties | Flexible coatings on pharmaceutical tablets; adhesion interfaces in building materials | Enhances durability and consistency of films/adhesive layers |

| Thermal gelation | Gelation behavior at certain temperatures | Formulations requiring temperature-controlled gelation | Provides thermally responsive structural stability and viscosity tuning |

| Surface activity | Surface-active characteristics aiding dispersion and wetting | Inks, coatings, food preparation, etc. | Improves wetting, dispersion, and appearance quality |

| Compatibility with other materials | Compatible with a wide range of materials; easy to formulate with | Multicomponent formulations such as paints, binders, food additives, etc. | Facilitates formulation and expands application scope |

| Other characteristics | Good thermal stability and chemical compatibility | Wide range of applications | Provides overall performance improvements |

What are the Applications of HPMC in the Construction Industry?

HPMC is a popular additive in construction due to its water retention, workability, and adhesion properties. Let’s explore where it is implemented within the industry.

In construction, HPMC is widely used in cement-based materials, such as tile adhesives, wall putties, renders, and self-leveling compounds. It improves workability, water retention, and adhesion strength.

- In tile adhesives, HPMC prevents rapid water loss, ensuring proper hydration of the cement and a strong bond between the tile and the substrate.

- For wall putties and renders, HPMC enhances crack resistance and provides a smoother, easier-to-apply finish.

- In self-leveling compounds, HPMC controls the flow and prevents segregation of the materials, resulting in a level and uniform surface.

- When used in mortar, HPMC improves the bonding strength between the mortar and the substrate by increasing the water retention of the mortar, which can effectively prevent cracking.

What are the Pharmaceutical and Food Industry Uses for HPMC?

In pharmaceuticals, HPMC is used as a binder in tablets, a film-coating agent, and a controlled-release matrix. In food, it acts as a thickener, stabilizer, and emulsifier.

As a binder in tablets, HPMC helps to hold the ingredients together and ensures the tablet maintains its shape. As a film-coating agent, it provides a smooth, protective layer around tablets, making them easier to swallow. Its controlled-release properties allow medications to be released slowly over time. In food, HPMC thickens sauces, stabilizes emulsions to prevent separation, and creates food gels with desirable textures. HPMC is generally recognized as safe (GRAS) by regulatory agencies for use in food and pharmaceuticals when used according to good manufacturing practices.

HPMC vs. CMC: Which is Better?

HPMC and CMC (Carboxymethyl Cellulose) are both cellulose ethers but have different properties and applications. Let’s examine their key differences.

HPMC is non-ionic, offering better stability and compatibility in various formulations, while CMC is anionic and may be more susceptible to interactions with other charged ingredients.

The key chemical difference lies in the substituent groups attached to the cellulose backbone. HPMC has methyl and hydroxypropyl groups, while CMC has carboxymethyl groups. This difference affects their performance. HPMC generally provides better thickening efficiency, superior water retention, and excellent film-forming properties compared to CMC. These properties make HPMC more suitable for construction applications like tile adhesives and renders. On the other hand, CMC is often preferred in applications like detergents, where its anionic nature can be advantageous. Cost can also be a deciding factor, as CMC is often less expensive than HPMC.

Understanding Cellulose Ether Grades

HPMC comes in various grades, each with unique properties and best-suited for specific applications. What’s the difference between them?

Cellulose ether grades vary according to particle size, viscosity, and degree of substitution, influencing its performance in different application scenarios.

Viscosity grades are typically measured in centipoise (cP) using a specific solution concentration and temperature. Higher viscosity grades result in thicker solutions, ideal for applications requiring strong thickening effects. Substitution grades, referring to the amount of methyl and hydroxypropyl substitution, also impact properties like gelation temperature and solubility. Finer particle size can improve the dissolution rate and dispersion of HPMC in a mixture, ensuring uniform performance. Selecting the right HPMC grade based on the desired viscosity, substitution level, and particle size is crucial for achieving optimal results in any given application.

Source High-Quality HPMC from Hixen

Hixen is a leading exporter of cellulose ethers, including HPMC, with 15 years of experience, supplying to South America, the Middle East, Africa, North America, and Europe.

Hixen offers a comprehensive range of HPMC grades to meet diverse application needs. Our HPMC products are available in various viscosity ranges, from low to high, and are manufactured under strict quality control standards. We hold relevant certifications to ensure the quality and consistency of our products. Backed by 15 years of experience, Hixen’s dedicated team provides exceptional customer service and technical support, assisting you in selecting the optimal HPMC grade for your specific formulation requirements.

Conclusion

HPMC is a versatile cellulose ether used in construction, pharmaceuticals, and food for its thickening, binding, and film-forming properties. It offers improved workability, water retention, and safety. Its specific characteristics and grade variations make it adaptable to a wide range of applications. Contact Hixen today to learn more and request a free sample.